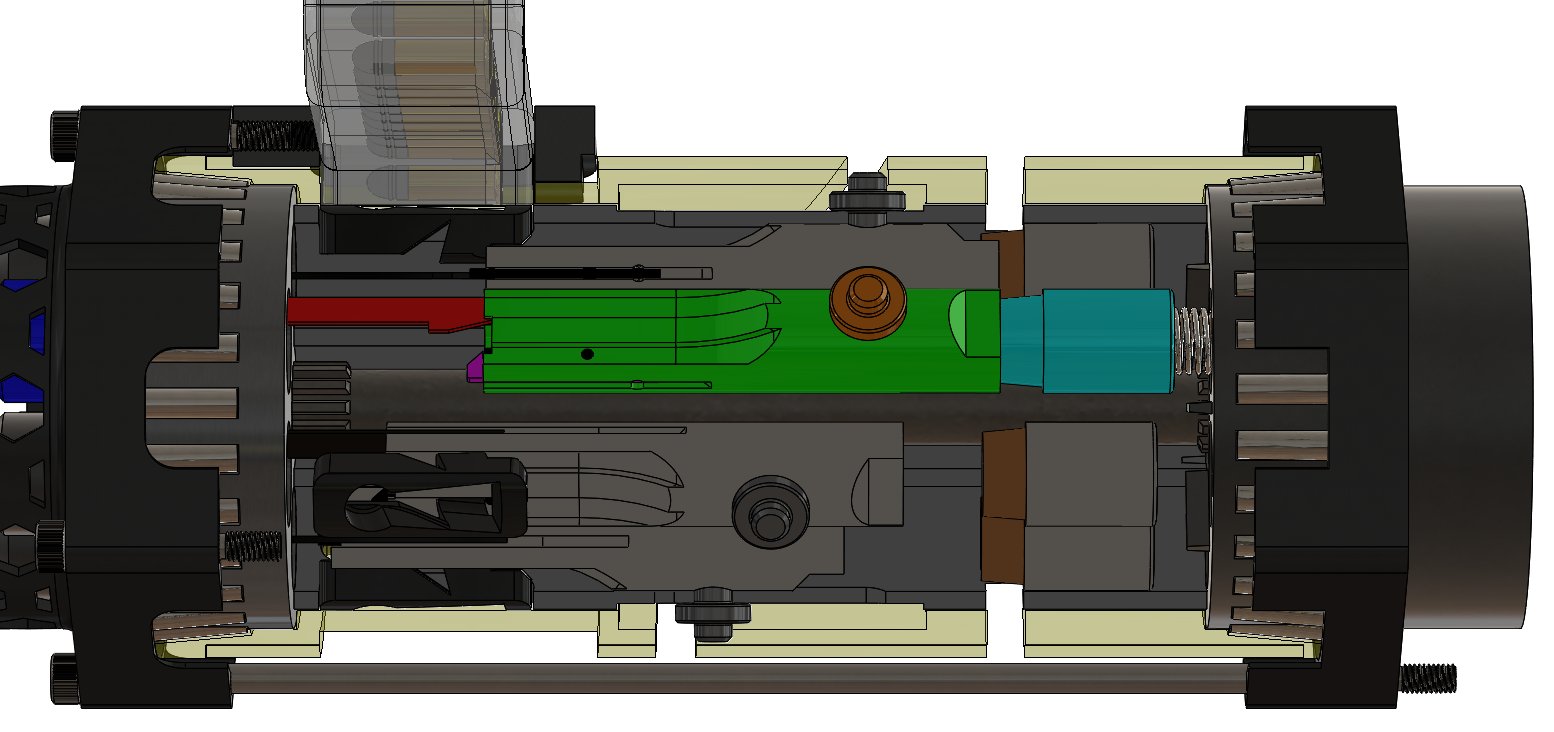

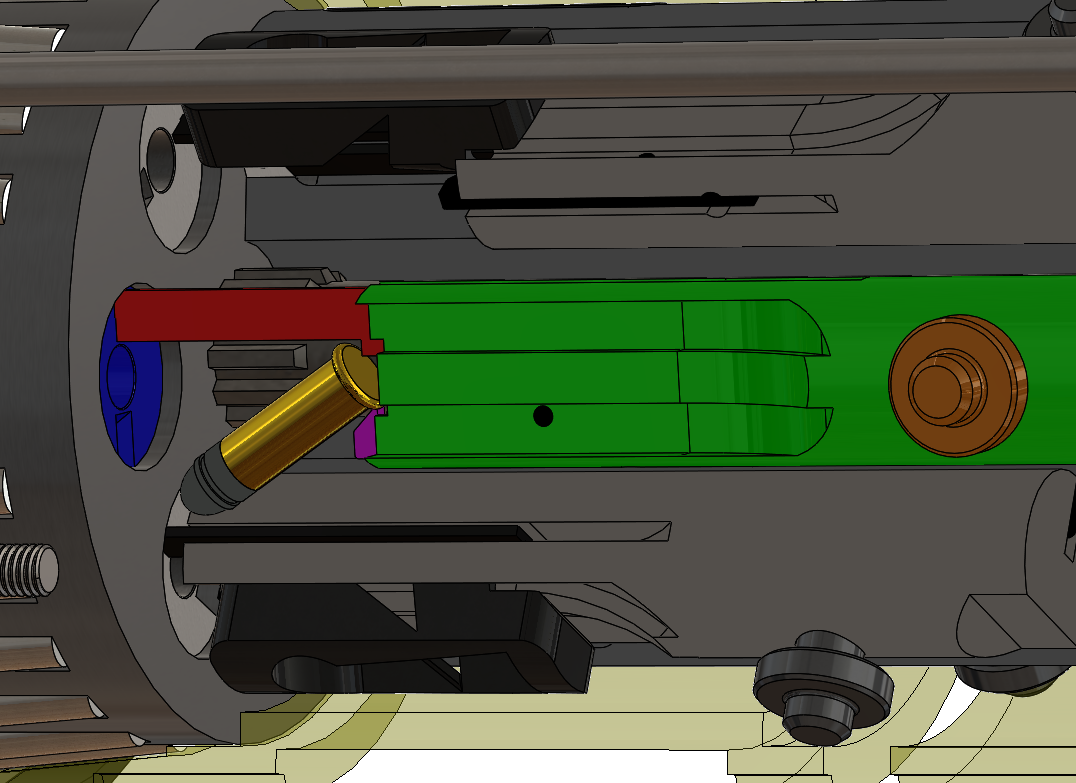

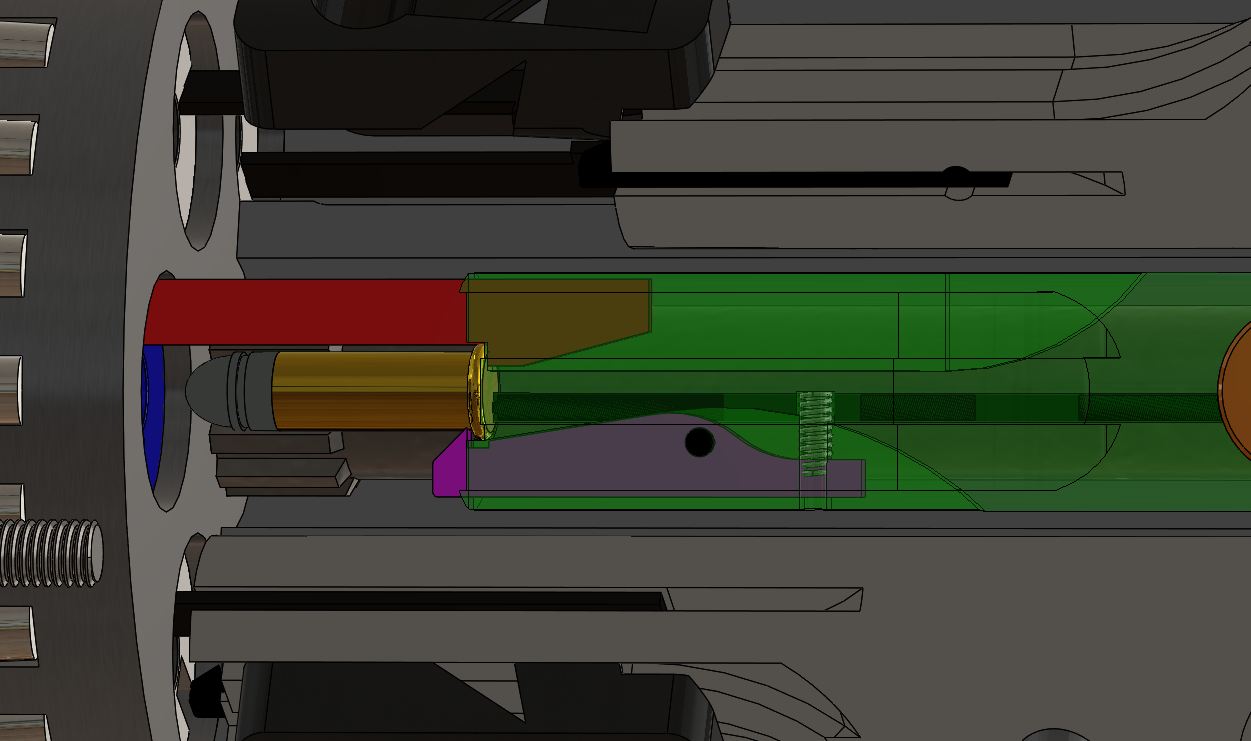

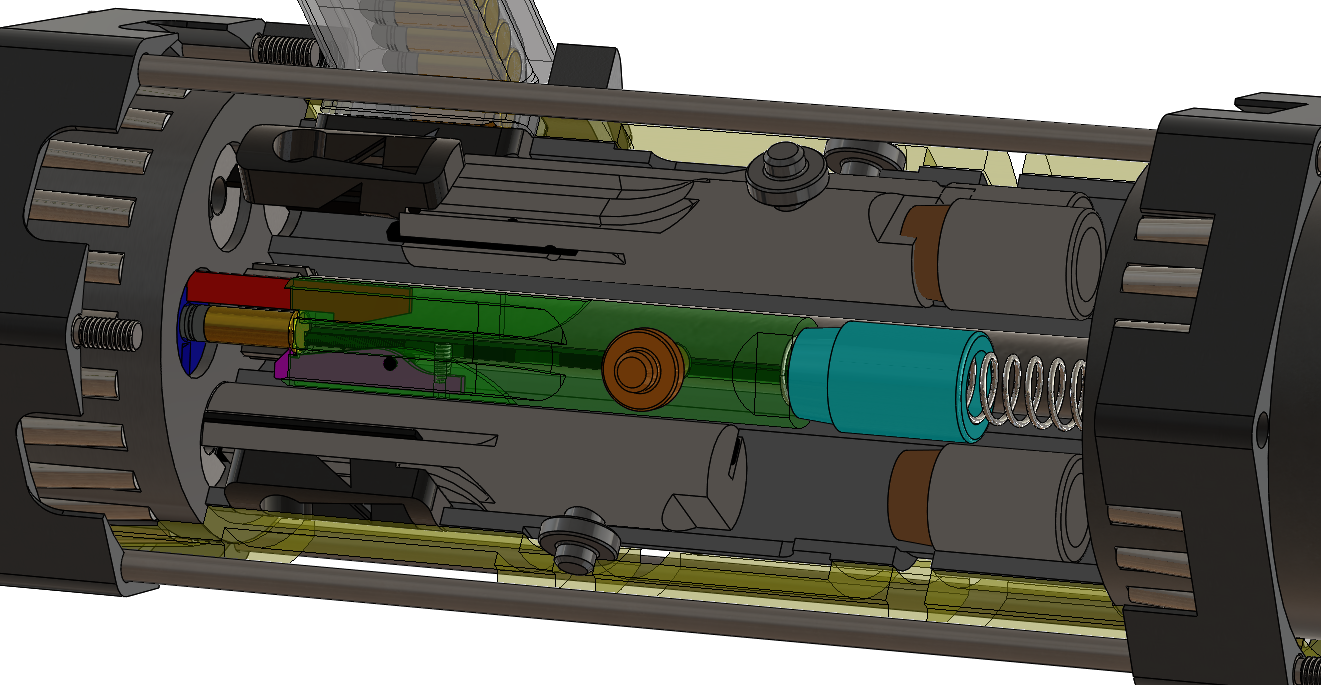

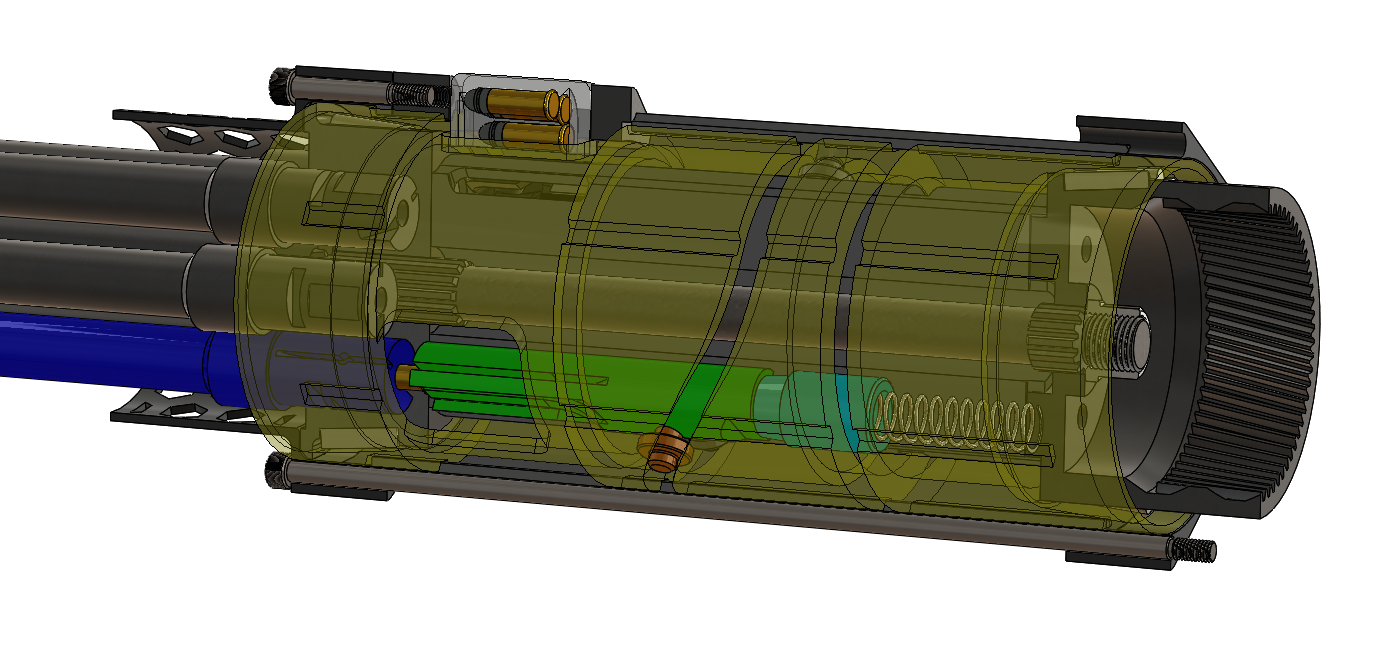

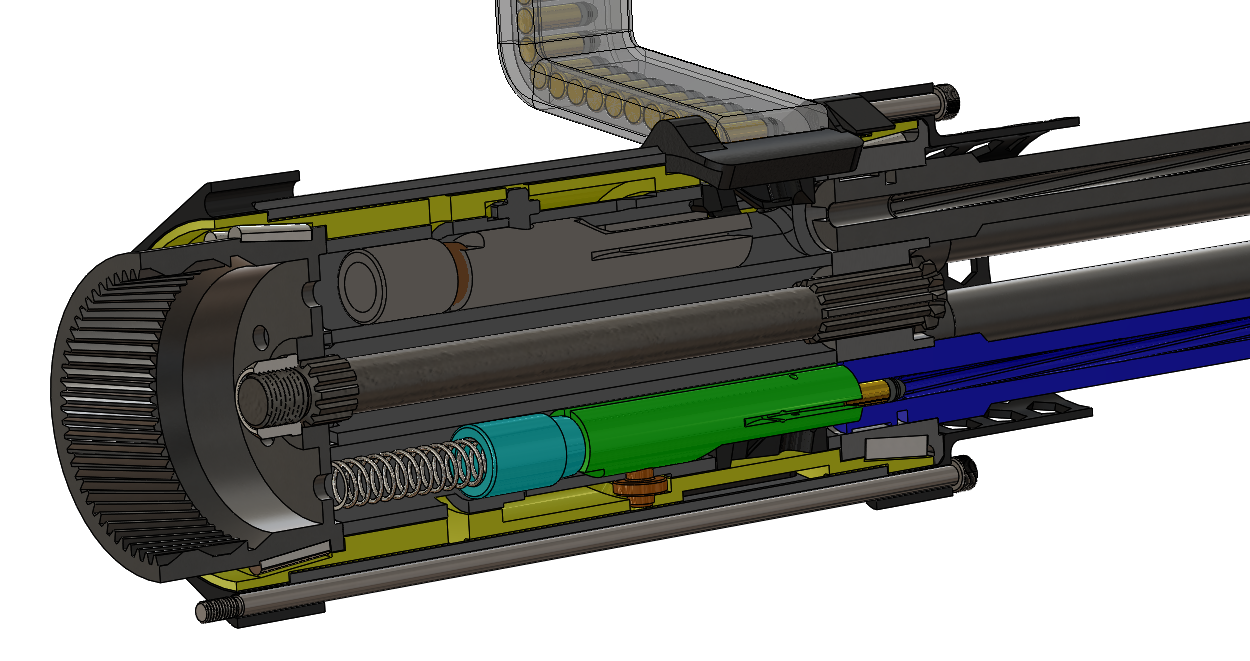

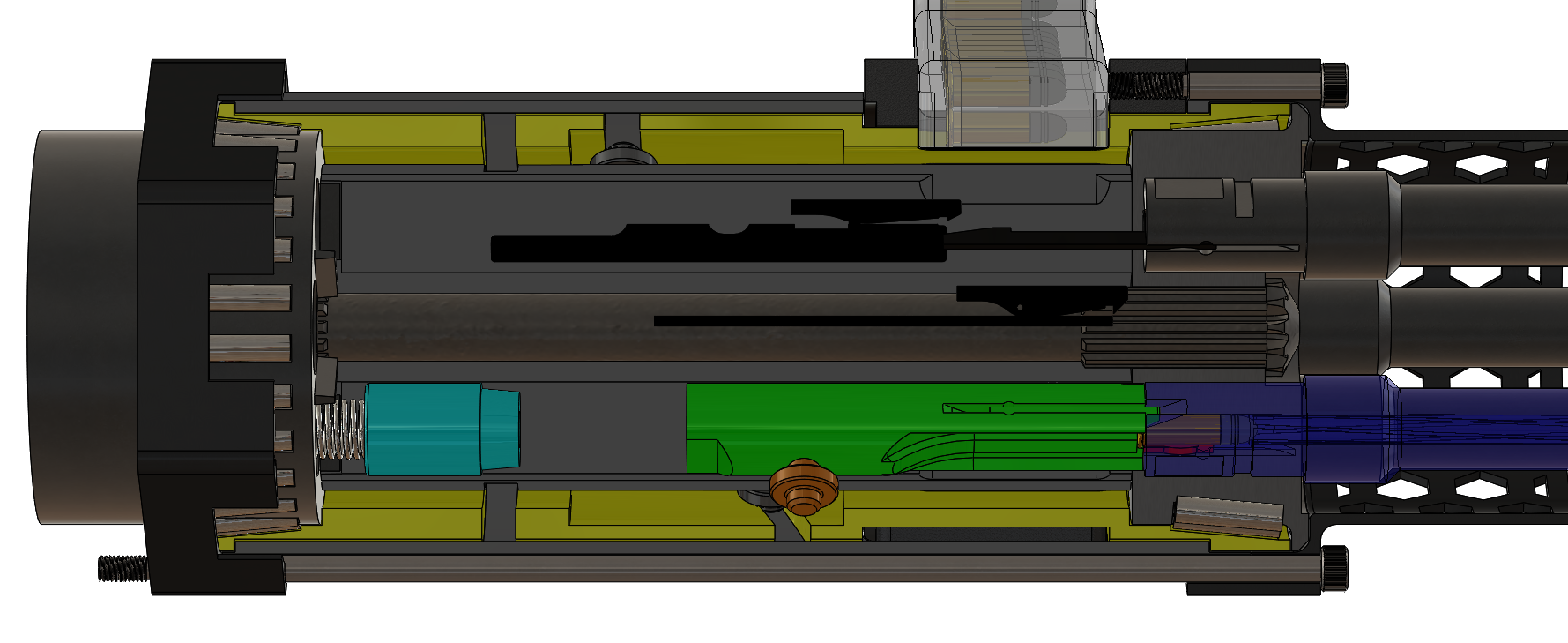

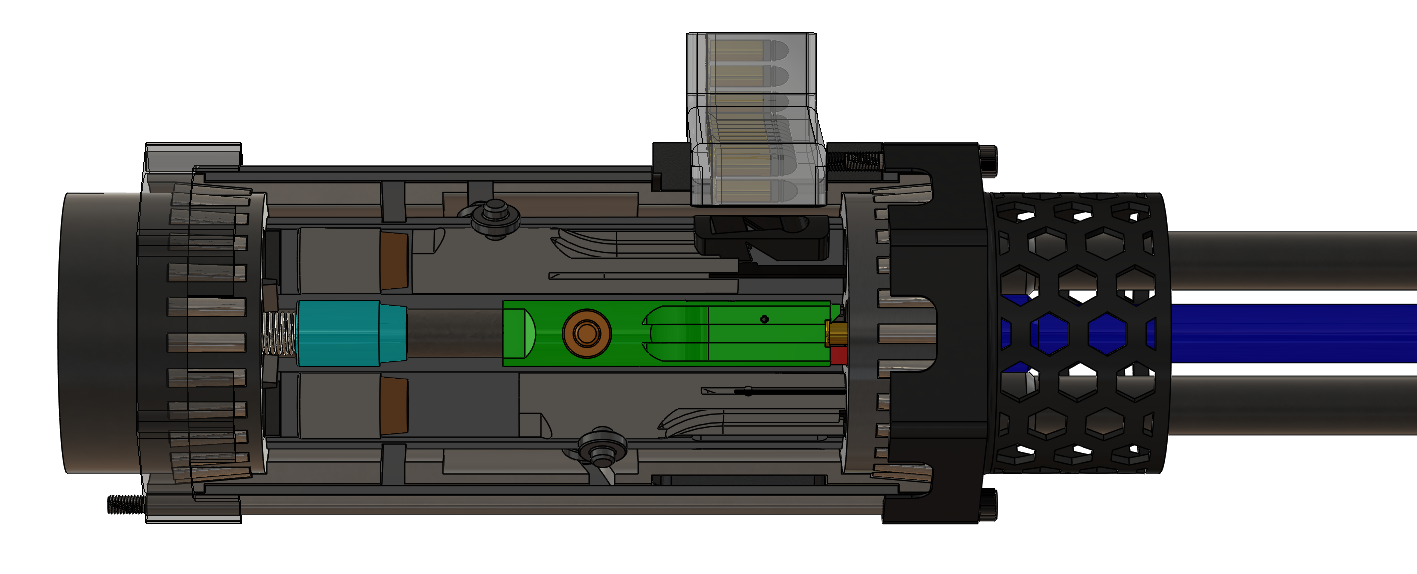

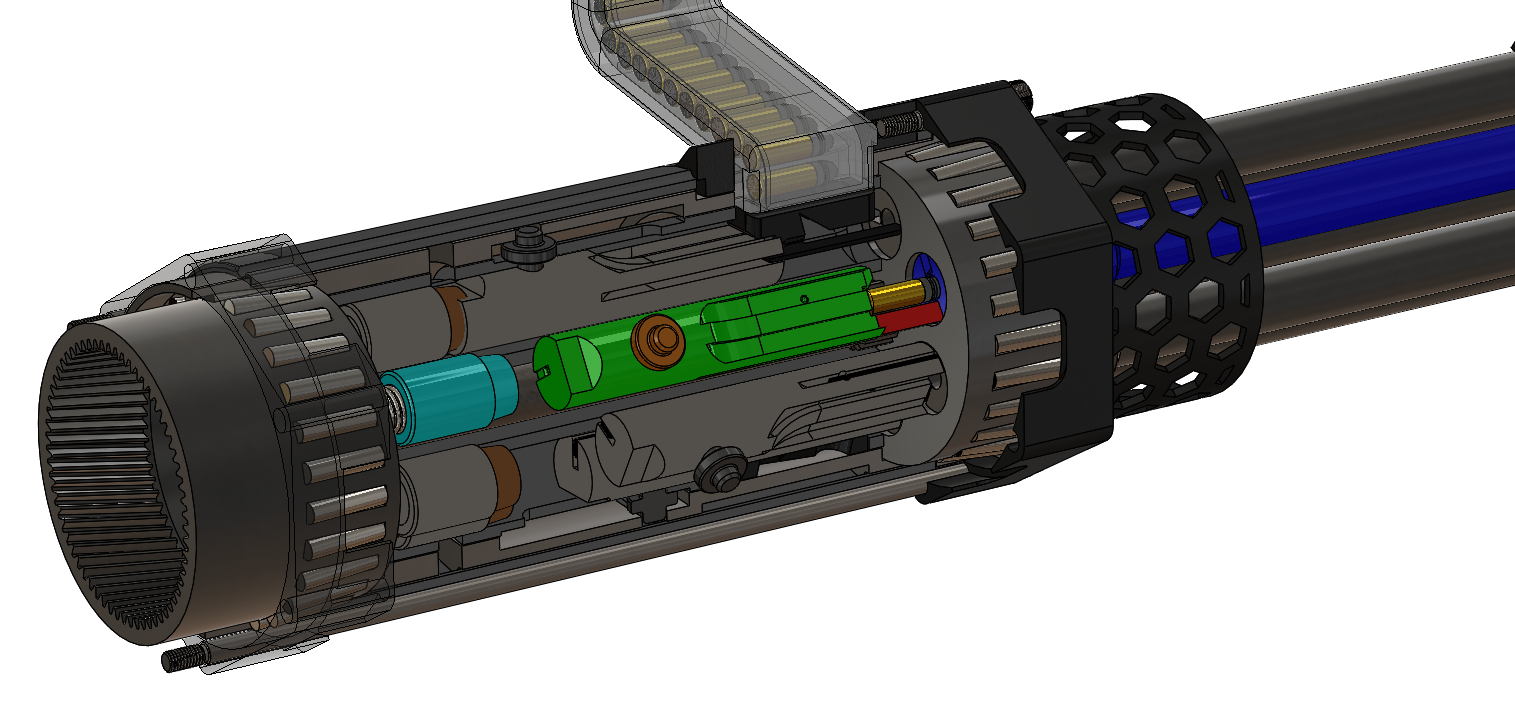

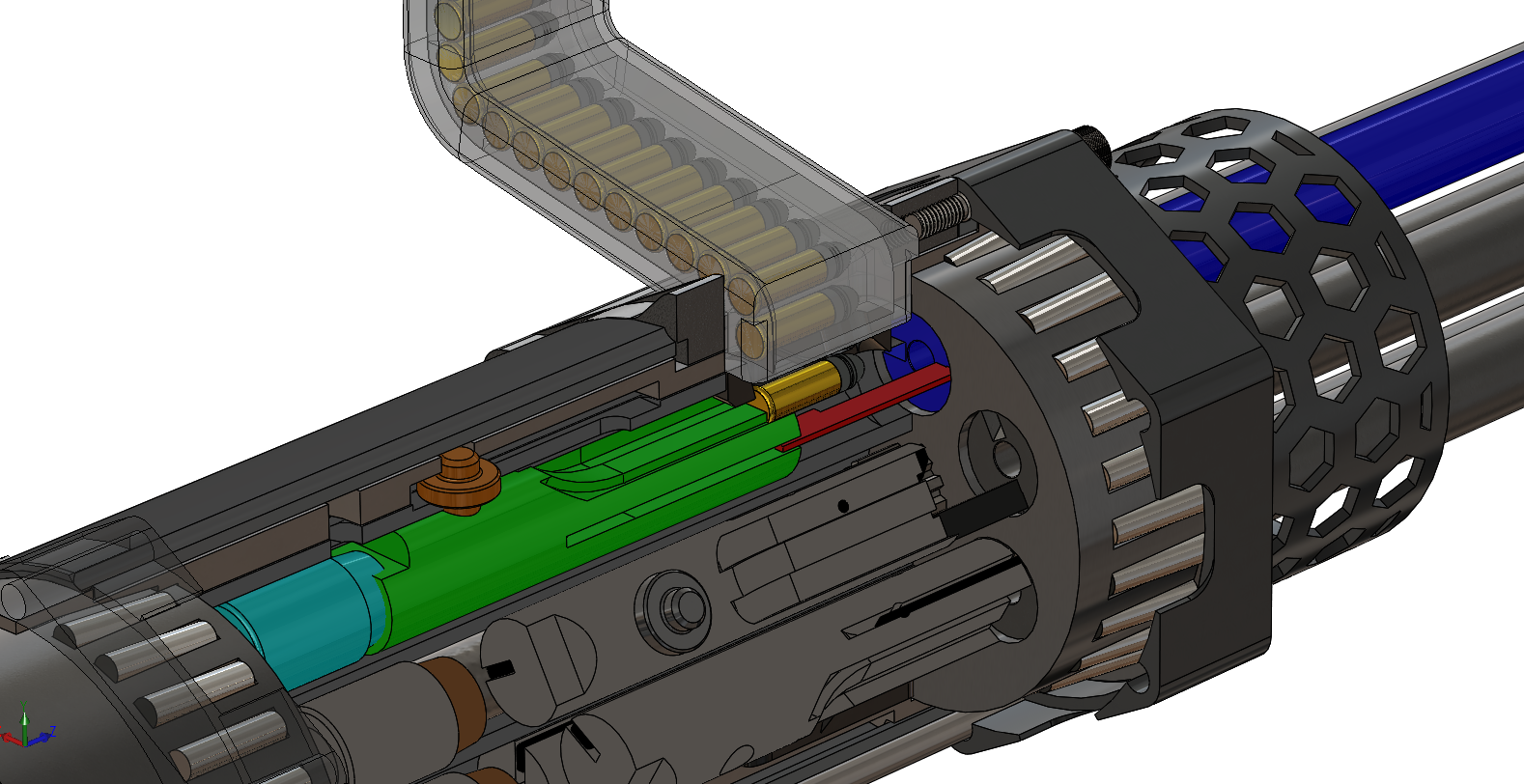

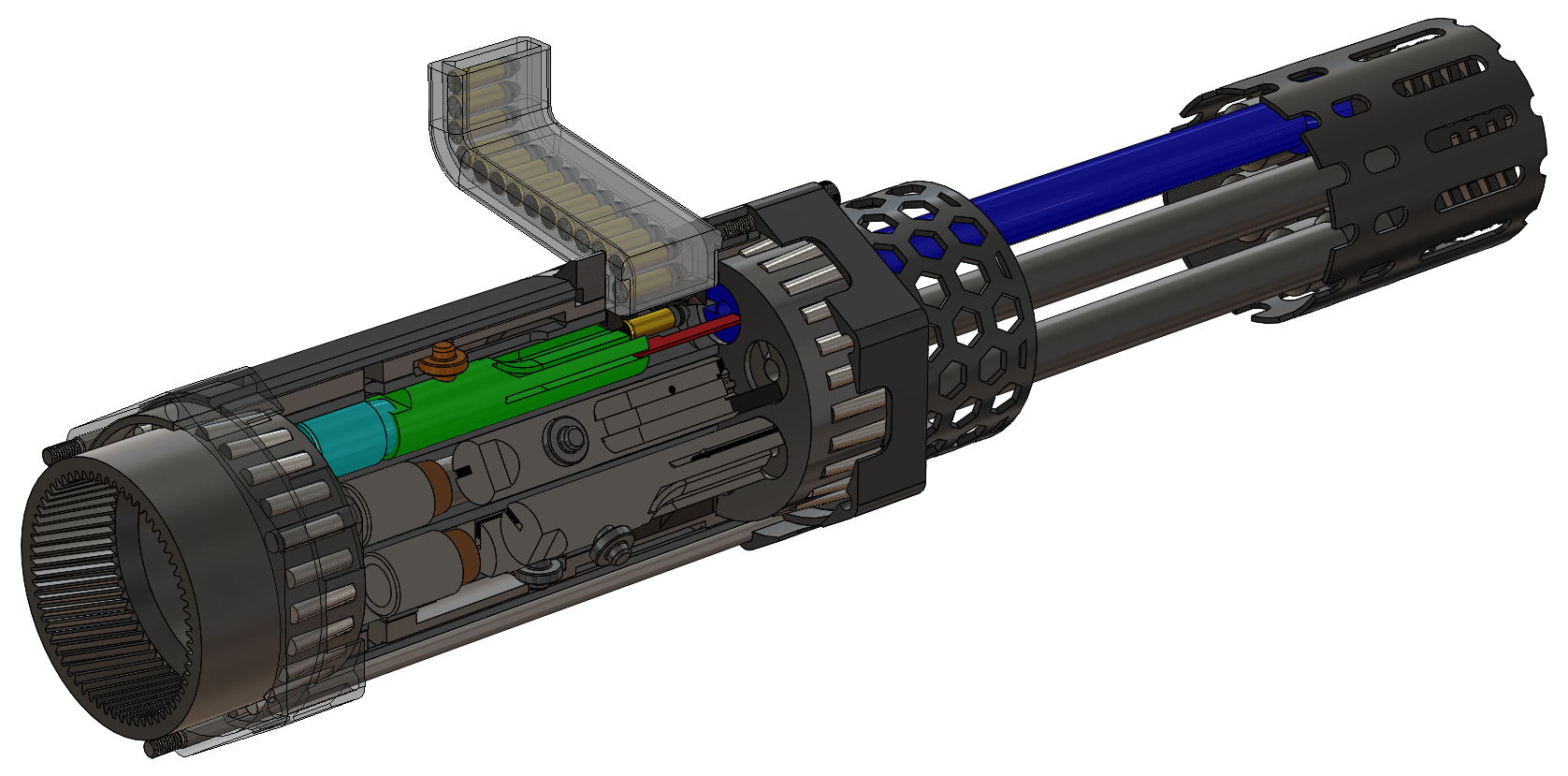

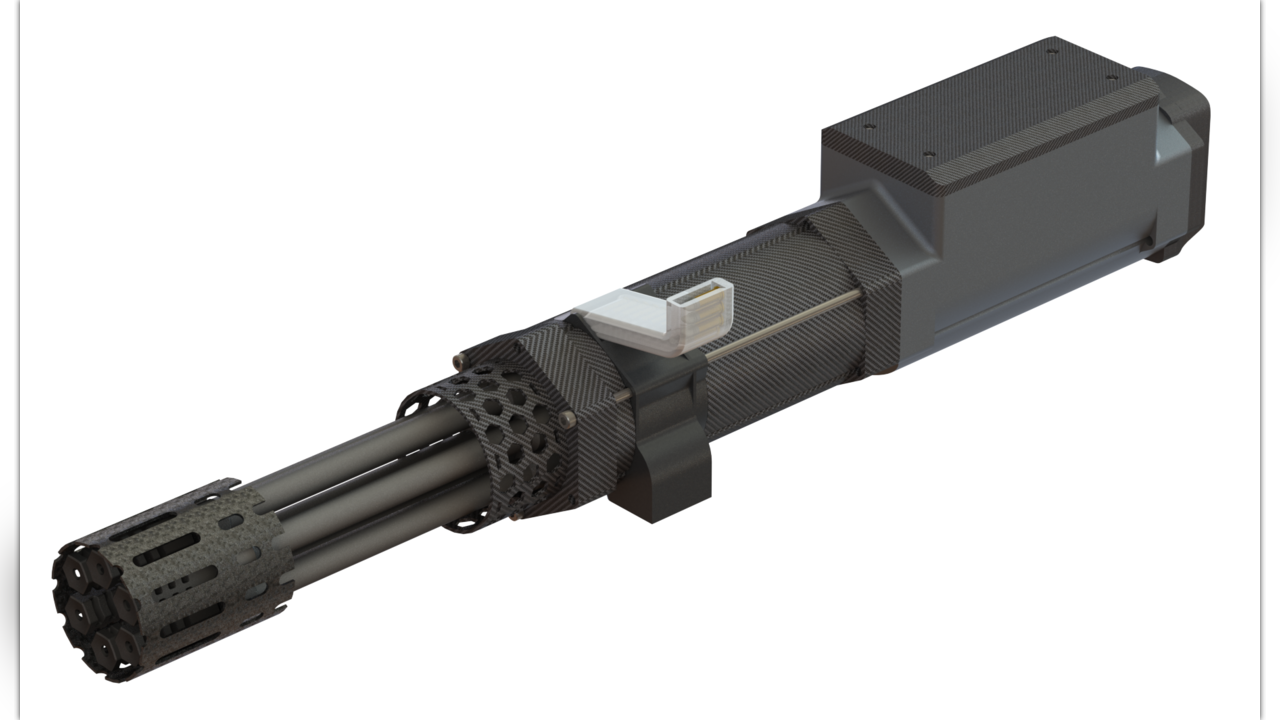

Nanogun update 003 – 2019-01-28 Greetings Innovators and Supporters, We’re now on our third week of the fundraiser for this project and have no new contributors to shout-out. We didn’t expect this project to take off quickly, and that assumption has proven correct so far. But, that’s okay. The project will move forward as slowly or as quickly as the funding permits. For this week’s update, I wanted to provide a simple overview of how the Nanogun will cycle. That is, how it will go through the mechanical process of loading and firing a round. This description isn’t going to cover the feeding mechanism, as that is a monster onto itself, but will just cover the mechanics of putting the round into the barrel, initiating the primer, and removing the spent casing. Before we get into the details, there are some terms which should be defined; Cartridge – an assembly of Projectile (bullet), Casing (brass shell), Propellent (powder), and Primer. Breach – The opening in the receiver or body of the firearm whereby a cartridge may access the chamber. Chamber – The cavity in which a cartridge is seated, which only permits entry of the cartridge in one direction. Bolt – The mechanical component which closes the breach and seals the chamber. The bolt may also provide or contain mechanical means of initiating the primer (firing pin). All firearms, with a few exceptions, work on virtually the same principal, with minor variations of how each step in the cycle is performed. Regardless of the type of firearms, the following steps are followed in the mechanical cycle; 1) Feeding A cartridge is transferred from the reservoir of ammunition into a position where it can be moved into the chamber. The “reservoir” may be a magazine, a belt of linked cartridges, or just a pouch full of loose rounds. Regardless of the type of reservoir, the “Feeding” step simply involves moving the cartridge into a ready position for the next step. 2) Loading The cartridge is moved from the Feeding position into the chamber and seated fully. Loading usually involves pushing the cartridge from the magazine into the chamber by closing the breach with the bolt but may also include pushing a cartridge into a chamber with your finger before closing the breach. This step ends with the breach blocked by mechanical means, and the cartridge seated in the chamber. 3) Locking The breach and chamber are closed by mechanical means, with some form of physical barrier in place to counter the forces produced when the cartridge is fired. This physical barrier might include locking lugs on a rotating bolt, a roller delay mechanism, a breach block which moves in an axis perpendicular to the force, the spring pressure from the return spring, or any number of methods employed to achieve the same effect. Regardless of the method used, the result is the same; one end of the barrel is blocked, providing only one direction for gasses to propel the projectile. Locking, in a gas driven system, also provides an effective delay in opening the chamber. This permits the pressure in the chamber to dissipate before it is opened. This ensures that the casing can be extracted from the chamber safely and easily; reducing the swell in the cartridge and preventing a case rupture from unsupported pressure. 4) Firing The cartridge is initiated, causing the propellant to expand, driving the projectile down the bore of the barrel in the direction of lease resistance. With the chamber locked, the direction of lease resistance is away from the bolt face. 5) Unlocking The breach and chamber are opened by mechanical means, permitting the extraction of the empty casing / cartridge. Unlocking may be driven by mechanical means or by user interaction. 6) Extracting The empty casing or unfired cartridge is removed from the chamber. This may be performed by a mechanical devise, such as an extractor attached to a bolt, or may be done by user interaction. Regardless of the method, the obstruction in the chamber is removed in this step. 7) Ejecting The empty casing or unfired cartridge is expelled from the breach. This may be performed mechanically or by user interaction. Regardless of the method, the result remains the same; the breach area is devoid of a casing or cartridge and is ready for the next cartridge. 8) Cocking The hammer or striker is moved back into a ready position and is locked into this ready position by a trigger mechanism. Note: Cocking may occur before, after, or during the extraction and/or ejection phases. Cocking may be performed automatically or by user interaction. The cycle for the Nanogun is no different than the cycle described above. Each bolt assembly follows the same process as it rotates around the primary axis. In the case of the Nanogun (and all other Gatling style machine guns) the movement of the mechanism is controlled by a cam path and the cycle process is driven by a motor rather than gasses or direct user interaction. The following describes the cycle of one mechanism in the cluster of six; Note: for the sake of simplicity, the relevant components in the mechanism have been highlighted in the images attached. The remaining mechanism may not accurately represent what is going on simultaneously; as the focus for this demonstration is the highlighted components. 1) Feeding The Nanogun is fed by a hopper of loose cartridges. The process for orienting the cartridges into a correct alignment for feeding into the breach will be covered in a future update, since this process is complex enough to warrant glazing over in this update. Suffice it to say that the rounds will be presented to the breach in the correct orientation. Loose rounds are fed into the breach using gravity and a mechanical interface which is still in development. The rounds are seated into a ready position, similar to how a .22 round would be seated in a magazine, with the exception being that the round is fed from the top down, and there is no spring force pushing on the round from the top. 2) Loading The round is ‘stripped’ from the ready position feed lips, similar to how a .22 round would be stripped from the magazine lips in a standard magazine fed rifle. As the barrel cluster assembly rotates, each bolt is driven forward by a cam path (not shown) by the CAM pin (orange). This motion permits the round to be stripped as the mechanism rotates. 3) Locking Once the Bolt assembly has moved the cartridge into the chamber, locking is achieved simply by providing a flat face for the cam Pin to act against. In this case, it is the cam path itself. Considering the low amount of pressure produced by a .22LR cartridge, this should provide sufficient locking force. Larger calibers with higher pressure require a locking mechanism with more robust lugs. 4) Firing Once the bolt mechanism reaches 180 degrees of rotation, the striker should have already been driven forward by its spring, initiating the primer and firing a round. The ‘trick’ here will be timing the triggering mechanism to ensure the round is fired at the correct position, while the bolt is locked forward completely. 5) Unlocking Once the Bolt mechanism has passed the 180 degree mark, they will be drawn back by the cam path. This basically acts as unlocking the chamber. 6) Extracting Each bolt assembly includes an extraction claw; a hook-shaped metal plate that engages the casing by its rim, permitting it to be withdrawn from the chamber, show in the below image as a purple component. The extraction claw has a small spring acting upon it to ensure that it remains engaged to the cartridge rim. 7) Ejecting As the bolt mechanism is drawn backwards, and the casing is withdrawn from the chamber, it eventually passes the ejection post. The ejection post is a metal plate with a surface that will interfere with the base of the cartridge as the bolt mechanism is drawn backwards. One edge of the cartridge face is forced away from the bolt face, while the opposite edge is held by the extraction claw, causing the cartridge to tilt. In this instance, the cartridge is tilted downwards, permitting it to fall straight down on the side of the mechanism body. 8) Cocking As the bolt mechanism is driven backwards by the cam pin riding in the path, it pushes the striker backwards with it. Once the striker passes a specific point, it will catch on the sear, locking it to the rear until the sear is actuated again at the 180 degree position. The sear mechanism is still in development. Once this process is complete, the bolt mechanism is returned to the feeding position and the process repeats. The high rate of fire produced by this type of machinegun can be directly attributed to quick successive repetition of the aforementioned process, multiplied by the number of barrels / bolt mechanisms in the cluster. That pretty much covers the mechanism in its simplest terms. There are still several issues to be addressed with the current design, but nothing insurmountable. The more funds we can raise, the more we can do with this project. If you have any questions regarding the firing cycle, or our ongoing design; please feel free to contact us. Next week, we will delve into the manufacturing methods we’d like to incorporate and why. In the meantime, we’re still interested in your ideas for test targets; please feel free to drop suggestions in the comments or contact us directly. Cheers, Ryan

Here's the campaign that needs your help

Delete media item?

Delete this item from the media gallery? It will also be deleted from any related story update.

Set as ?

The campaign video will appear in social media and email.

The campaign cover picture will appear in social media and email.

The will appear at the top of your campaign page and in social media and email.

Reset ?

It will be removed from the top of your campaign and won't be used as default in social media and email. The will remain in the media gallery.

Delete update

Delete this story update?

Any pictures or videos will remain in the campaign's media gallery.

Edit Story update

Modifications will affect the activity feed only. Emails cannot be modified after they have been sent.

{{.