Your share could raise $30

Before you go, did you know that simply by sharing this campaign, you could help it raise $30? It's an effective way to support the cause.

Share this campaign No thanksEnable Innovation Product Development Inc. hasn't added a story.

Have you ever had a crazy idea?

We have a crazy idea...

If you could design anything, what would you design? Would it be practical? Would it be awe-inspiring? Would it be fun?

Enable Innovation Product Development Inc. helps innovators and entrepreneurs realize their ideas and dreams, by offering engineering services and support, as needed. But, sometimes, we have our own ideas. Sometimes those ideas are so impractical and fantastic that we want to share them with everyone.

This is one of those ideas.

What is “the Nanogun”?

Remember in Terminator 2, when everyone’s favourite T-1000 was

strafing police cars out of a window with a hand-held machine gun with

rotating barrels? That’s a mini-gun.

Movie magic would have us believe that someone could actually wield a minigun unsupported, from the hip, like Blain in the original Predator movie. Unfortunately, wielding a rifle caliber minigun would be significantly difficult, and isn’t likely to be done easily.

But, if that minigun were super-small, and super-light… well, that’s a horse of a different colour.

This is what spawned the concept of the Nanogun.

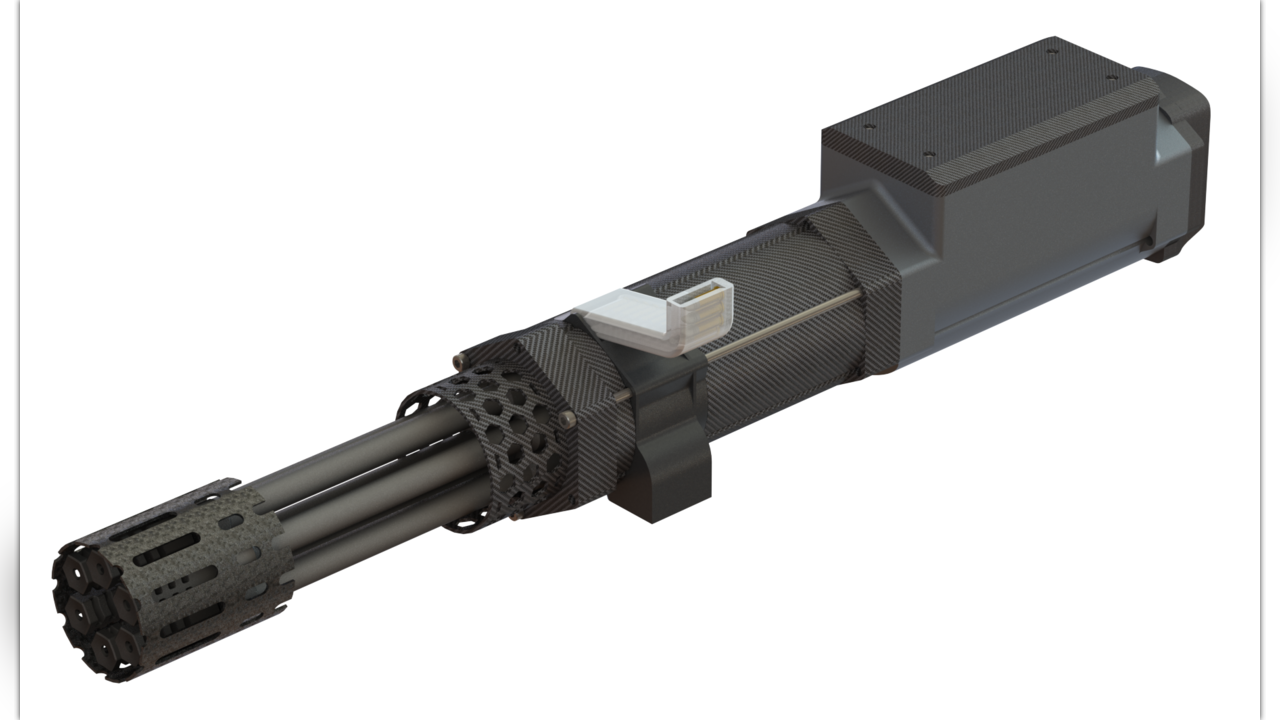

The “Nanogun” is a .22 caliber, 6 barreled, rotary machine gun, similar to the M134 Minigun, or the GAU-8 Avenger cannon… except significantly smaller than either.

Why does Enable Innovation want to design minigun?

With their high rate of fire, insatiable appetite for ammunition, and mechanical wizardry; rotary barrel cannons, or Gatling Guns, have long drawn the curious attention of firearms enthusiasts and the general public alike.

As an engineering project, a rotary machine gun provides some interesting challenges, as well as the opportunity for innovation. These innovations include the development of mechanisms and mechatronic systems using the most advanced technologies available; technologies such as additive manufacturing, nano-coated materials, advanced micro-controllers, ultra-lightweight materials, and cutting-edge design tools.

Our goal with this project is to produce something interesting, which explores the limits of these technologies and tests the capabilities of our engineering team. Since our engineering team derives most of its collective experience from the firearms and defense industries, this project seemed like a perfect fit.

Why a 22LR minigun?

Simple Answer: Math and Money.

Most people who have seen a minigun in action dream of one day being behind the trigger of one. The limiting factor for most people, aside from the legality, is the cost… and not just the cost of the gun itself, but of the ammo.

For example; an M134 costs approximately $100,000 for just the gun. This particular gun fires 7.62mm NATO linked ammunition. A box of 200 rounds, with link costs approx. $175 CAD. The rate of fire for the M134 is 3000 RPM, or 50 rounds per second. Therefore, 4 seconds of fire will cost $175 CAD… or $43.75/second

22LR ammo may be purchased by the bucket (1400 rounds) for $120 CAD… that’s 8.5 cents per round. With the same rate of fire (3000 RPM); it works out to $4.25 per second of fire.

Aside from the ammunition costs, the mechanism for a 22LR rifle is significantly simpler than larger calibers, and since the rounds have a rim, they may be oriented and fed without the need for a linked belt, or the mechanism to de-link the rounds. These factors reduce the complexity, weight, size, and subsequently, the cost to develop.

Size and weight are other benefits; a 22LR rotary machine gun would be light enough, with low enough recoil, to operate with one hand. Allowing the user to fulfill their fantasy of spraying rounds like Nemesis from the Resident Evil franchise of games.

What does Enable Innovation want it to do? (Performance)

There are three major objectives for this project;

- Develop a functional prototype .22LR caliber, rotary barrel

machine gun with the following specifications;

- .22 Long Rifle Caliber

- 6-barrel configuration, with 10” long barrels

- Loose ammunition feed mechanism (large hopper / vibratory bowl feeder, no belt)

- Battery powered using a 24v system and conventional cordless drill batteries

- Adjustable rate of fire controlled by micro-controller

- Maximum feed rate of 3000 rounds per minute

- Light weight, under-slung configuration to permit one-arm, unsupported operation

- Include an integrated sound suppression system to reduce muzzle report

- Incorporate advanced technologies, products, and processes in the

design, development, and production of the functional prototype,

including the following (where possible);

- Carbon wrapped barrels

- Nano coating for wear surfaces and barrel bore

- Additive manufacturing for metal, polymer, and composite components

- Component optimization using CAD models, Solidworks Simulation, and Finite Element Analysis

- Document our process and make it available;

- Design journal, including engineering notes, diagrams, and concept imagery generated during development

- Regular video updates for upload to youtube and other social media platforms

- Test videos, including highspeed and thermal filmography of test firing

- Project imagery, including digital renderings, in-production photos, and testing photos

How will Enable Innovation achieve this?

To achieve the aforementioned objectives, we have broken this project down into three distinct phases as follows;

Phase 1: Development

The development phase is currently being conducted by Enable Innovation staff, with input from contributing sponsors and manufacturers.

Development on the control system and mechanism began in the summer of 2018, with limited resources and funding available.

The budget estimate for phase 1 is $100,000 and requires approximately 6 months to complete.

The goal for this phase is to complete the prototype design of the Nanogun and conduct non-physical / virtual testing of each component and the mechanism as a whole.

Components will be optimized for manufacturing using modern and advanced processes, such as metal additive manufacturing. Outside companies specializing in these processes will be consulted during the development phase to ensure optimal manufacturing results.

Phase 2: Prototype Production

For prototype production, we will be engaging with contributing manufacturers as much as possible to ensure the design intent is well understood. The design of individual components will be adjusted and optimized with input from manufacturers to ensure production processes suit the components and vice versa. Prototype assembly will be conducted by Enable Innovation staff.

The budget estimate for phase 2 is $75,000 and requires approximately 4 months to complete.

Phase 3: Testing & Fun

Once a functional prototype has been manufactured, it will be subjected to a battery of tests to confirm functionality and safety.

Test protocols will be specified by Enable Innovation staff, and testing may be carried out by a third party if necessary.

Test protocols will include;

- Function / operation using highspeed filmography

- Heat dispersion and heat effect on function using FLIR

- Rate of fire control

- Sound pressure audiology for suppressor technology

- Failure mode analysis and minimal endurance testing (mechanism only)

The test protocol will not include any testing to verify the Nanogun for broader commercial production or Defense applications, as these test fall outside the scope of the project.

When the mechanism is proven, and operational safety is verified; prototype Nanoguns will be used to produce promotional media, as well as for live public demonstrations at appropriate venues.

The budget estimate for phase 3 is $25,000 and requires approximately 2 months to complete.

Has any work been done so far?

Yes! Initial concepts have been developed for the mechanical system, including the primary components of the gun itself; bolts, barrels, cam paths, drive components, etc.

Most of the electronic control system has also been developed to a prototype level using off-the-shelf micro-controllers (Arduino) and other readily available components.

And, this work will continue despite outside funding, for as long as the CEO can personally afford to pay for it... Unfortunately, without support, that won't be very long.

Who will be / is doing the work?

-

Ryan Pagnacco CD

CEO of Enable Innovation / Innovation Armoury

Mechanical Engineering Technologist Diploma

5+ Years of firearms engineering experience

Canadian Forces Combat Veteran, 15 years + 1 deployment (Afghanistan 2006)

-

Brenton Teed P.Eng

Senior Product Engineer, Engineering Adviser

Licensed Professional Engineer, registered with Professional Engineers of Ontario

10+ years of firearms engineering experience

Is this legal?

Yes. Of course it’s legal… if you have the correct licenses.

Enable Innovation Product Development Inc. maintains a Business Firearms License in Canada, specifically for the development and production of firearms which are classified as Prohibited by law. The Nanogun, by its very definition, will be considered a prohibited device in Canada, which means it may only be possessed by a person or company which has the necessary license. As such, upon completion of the design and prototype, the firearm will be registered with the CFO and RCMP as a prohibited device, intended for demonstration purposes only.

Can I purchase one?

Probably not. Unless you maintain a Canadian Possession / Acquisition license which indicates that you are permitted to own a prohibited machine gun; you will not be able to own a Nanogun.

But, that doesn’t mean you won’t be able to hold and fire one.

Our goal is to make several Nanoguns available for demonstrations and range events. There’s no point in making these unless we’re able to share the experience.

I live in the USA and have a License that permits Automatic Weapons. Now can I buy one?

Yes with an if... No with a but.

Yes, you could technically buy

one, if we were able to export them... but we haven't gotten there yet.

No, you can't buy one right away... but, if we are able to find a manufacturer in the USA with appropriate licensing, we would definitely be interested in opening sales in the USA.

Contact us; we'll talk.

What are the practical applications for the Nanogun?

None, really. We’re not going to pretend that there is a practical application for a 22 caliber machine gun with a variable rate of fire, but several components within the project have real world applications, as do the manufacturing methods we hope to employ.

For example; using processes such as additive manufacturing on a firearm demonstrates that these processes are suitable for industries which subject materials to extreme conditions similar to those found in the operation of a machine gun. As well, this project will provide the designers and engineers involved the opportunity to develop the Nanogun to suit these manufacturing processes, and optimize the design to improve weight, efficiency, and aesthetics.

How will my contribution be used?

Designing anything requires time. The more complex the design, the more time is required.

Your contributions will be applied to the cost of time and infrastructure to keep this project moving forward. These funds will be specifically allocated to the operation costs relating directly to the development of the Nanogun. These costs include; wages of engineering staff, materials & equipment relating to the Nanogun, and the production of prototypes.

What do I get for my contribution?

Though we haven’t started producing any marketing materials or swag for the Nanogun; we do have concepts in mind to promote the project and to spread the word. These ideas include morale patches, videos, and documentation.

We would like to produce a journal covering the development process to be distributed to our major contributors as well have it available for sale once the project is complete. But this is very much dependent on the funding available.

Either way we’d like to focus the funding on the project, and not distract ourselves from getting this thing made. If we distributed t-shirts, hats, stickers, patches and everything else; we’d spend more time and money sending those items out to our contributors rather than actually working on the project.

With that said; our goal is to take this crazy thing across Canada for demonstrations and trade shows. As a contributor, you would definitely be welcome to handle the Nanogun, and if appropriate for the venue, fire it… I mean, why build something this crazy without firing it as often as possible?

Is there any other way I can contribute or get involved?

Of course, there is. Are you an engineering student or professional

with experience in additive manufacturing, mechanism design,

automation, micro-controller programming, and / or Solidworks?

Are you a firearms enthusiast with relevant knowledge and / or

experience?

Do you own or operate a business with access to

5-Axis CNC manufacturing capabilities, or any other advanced

manufacturing capabilities?

We’ll be looking for all of the above during the course of this project. Feel free to contact us with your information.

Whether you decide to contribute or not; we appreciate that you've made it this far into our pitch, and thank you for your consideration.

Highlights

See all activity3Updates

Activity

Set as ?

The campaign video will appear in social media and email.

The campaign cover picture will appear in social media and email.

The will appear at the top of your campaign page and in social media and email.

Reset ?

It will be removed from the top of your campaign and won't be used as default in social media and email. The will remain in the media gallery.

Share

Embed

Share a link

Delete update

Delete this story update?

Any pictures or videos will remain in the campaign's media gallery.

Report campaign

Report submitted

Thank you. We take reports like yours very seriously. Our goal is to keep the community safe.

Please know that we may contact you for more information, but that we won't notify you personally of our decision. If the campaign remains available within a few days, it's likely that we determined it not to be in violation of our policies.

Thank you. We've already received your previous report. If the campaign remains available within a few days, it's likely that we determined it not to be in violation of our policies.

Tell us about the problem. Please fill in both fields below.

Record a video

Upload a video

Nothing grabs attention for your cause like a personal video. Take a minute or two to record one now. Record a short video message of support. Or upload one from your device. You can preview or redo your video before you post it.

Nothing grabs attention for your cause like a personal video. Upload a short video message of support. Upload a short video message of support. Or record one right now.

- Most effective video length: about a minute.

- Maximum length: 5 min.

- You can preview or redo your video before you post it.

Heads up! The existing video will be replaced.

Email your friends

Join our team

Your endorsement banner

Use your endorsement banner to tell why our cause matters to you. Such personal endorsements are proven to increase campaign contributions. When enabled, your endorsement banner appears at the top of the campaign for everyone who visits a link you shared.

You can always adjust your endorsement from the campaign Share page—even if it's been disabled.

Your message

Tell people why our cause matters to you. Your personal message will encourage others to help. Easy, effective, optional.

Say it in video

Short personal videos by supporters like you are incredibly powerful. Record one right now and you'll help us raise more money. Easy, optional, effective.

Add a personal goal

Set a personal fundraising goal. You'll encourage more contributions if you do. And rest easy. There's no obligation to achieve your goal or bad consequences if you don't. Easy, optional, effective.

We have a video!

Video thumbnail

We'd love to show you our campaign video. Want to take a look?

, you're already on the team.